![]()

What is Infinium T?

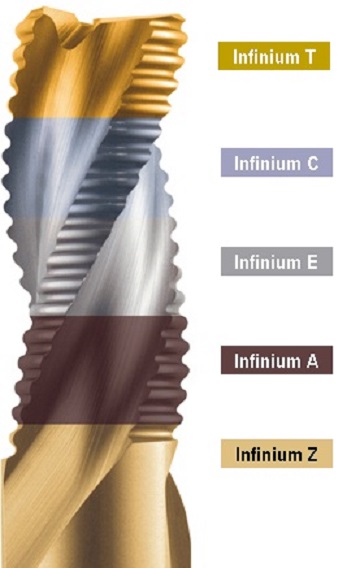

Infinium T is a Titanium Nitride based coating. Titanium Nitride was the first commercially available hard coating on the market. It took almost a decade to gain acceptance and has proven to be useful to this day. Although PVD Titanium Nitride has become a commodity coating, there are still many differences in the quality of the coatings among suppliers. It has a beautiful gold color and is very hard and wear resistant.

![]()

Crystallume’s Infinium T is optimized through a patented process to give you consistent coating properties. It is important to match these coating properties to the application and the quality required. For applications such as medical instruments or injection molds, the consistency, abrasion resistance, and quality will be most important, while for commodity drills and decorative applications the lowest price per piece may dictate the coating specifications. These differing properties can be gained through the adjustment of the temperature that the coating is applied at and the total thickness of the coating.

For which applications is Infinium T useful?Forming Tools

| Cutting Tools | Infinium T is an excellent choice for the machining of ferrous materials. Significant tooling lifetime improvements can be found for unalloyed and softer irons and steels (Rc<32). |

| Forming Tools | Infinium T provides forming tools such as punches and dies with a hard and lubricious surface. |

| Molds/Forming Tools | Infinium T is also a good release and abrasion resistant coating for plastic injection molding applications. |

| Medical | Infinium T is a biocompatible coating that has been approved for use in implants and surgical devices. In addition to improving wear resistance, it can also make sterilization and cleaning easier. |

| General | Infinium T is a general purpose coating which can reduce abrasive and adhesive wear. It’s brilliant color also makes it a good candidate for decorative applications. |

| Certification Available | AMS 2444 Class 1 |

![]()

What is Infinium C?

Introducing a carbon bearing gas to the Infinium T deposition process creates PVD Infinium C. The incorporation of carbon into the film increases its hardness and wear resistance, while lowering its coefficient of friction from the properties of Infinium T. These properties yield significant lifetime improvement in comparison to Infinium T coatings. Due to its increase in brittleness, Infinium C must be deposited as a multilayered coating in order to have adequate toughness for cutting applications.

Infinium C appearance can range from a near-gold appearance, to a copper color, to the silver-blue color typically found in the marketplace. The color depends on the carbon content and other coating processing factors in the composition of the final coating layer.

For which applications is Infinium C useful?

| Cutting Tools | Infinium C can be used in all cutting tool applications as a replacement to Infinium T. Cutting tools coated with Infinium C also perform well on Titanium and Nickel based alloys. Infinium T coated tools work best when coolants are used to control the temperature of the cutting tool. |

| Forming Tools | Infinium C can be used on punches, shear blades and dies. |

| General | Infinium C can be used as a general purpose wear coating on parts subject to abrasive wear. As a decorative coating Infinium C can be an attractive due to the range of colors available. |

![]()

What is Infinium E?

Infinium E is a Chromium Nitride based coating. Infinium E is a tough, wear resistant coating with exceptional corrosion resistance. It has higher oxidation resistance than Infinium T and Infinium C and, due to its chemical inertness, prevents adhesive wear.

Infinium E is silver in color and appears like polished stainless steel. It is an environmentally friendly coating and is harder than chrome plating.

For which applications is Infinium E useful?

| Cutting Tools | Some difficult to machine materials, such as copper and titanium, can be machined easier with Infinium E coated cutting tools and inserts. |

| Forming Tools | Infinium E is most commonly used to improve forming tool life as in dies for automotive parts. This coating works well under higher loads due to its excellent adhesion and shock resistance. Infinium E also performs well in hot forging applications due to its hot hardness and oxidation resistance. Typical applications include flanging dies, drawing dies, extrusion dies, punches and form rolls. |

| Molds | Molds for the injection molding industry also benefit from the Infinium E to decrease wear and sticking of plastics. |

| Medical | Infinium E coatings can increase the lifetime of components that need repeat sterilization. In these applications, the anti-corrosive and anti-sticking properties of the coating make it easier to maintain the cleanliness and sterility of components. Infinium E has excellent biocompatibility for external and internal medical devices that come in contact with bone, skin, tissue or blood. |

| General | Infinium E has better wear properties and can be polished to have the appearance of hard chrome plating. General use as a wear coating where increased toughness and corrosion resistance is required. |

![]()

What is Infinium A?

Infinium A is a multilayer Aluminum Titanium Nitride based coating. The development of PVD Aluminum Titanium Nitride based coatings is the most significant advancement in wear coatings since the introduction of Titanium Nitride. The addition of aluminum to the coating not only increases cold and hot hardness, but also can double the maximum operating temperature of Infinium A coated components. The aluminum in the Infinium A converts to aluminum oxide from the heat in these high temperature applications creating a ceramic layer in the coating. The oxidation onset temperature for Infinium A is 900�C, which is one of the highest commercially available oxidation temperatures for a PVD coating.

Infinium A has a violet black color and its hardness properties can be tailored by varying the aluminum content of the coating.

For which applications is Infinium A useful?

| Cutting Tools | Due to the increased oxidation resistance of Infinium A coatings, dry machining of hardened steels has become possible. The most significant improvement can be seen in the machining of materials with hardness greater than 50 Rc. Remember Infinium A requires heat to work best. Materials such as Titanium, Inconel, and stainless steels can also be machined at higher speeds easier with Infinium A coated carbide tools. |

| Forming Tools | Infinium A can be used as a protective coating for dies and molds that operate at moderate to high temperature. The coating helps protect the tool from wear, heat checking and thermal fatigue. |

| Medical | Not biocompatible. |

| General | Infinium A can be used as a beautiful, dark colored decorative coating and a general purpose wear coating. |

![]()

What is Infinium Z?

Infinium Z is a Zirconium Nitride based coating. Infinium Z is a complementary PVD coating to Infinium T. It has similar performance characteristics to Infinium T, with the exception of having a lower sticking probability when machining aluminum and aluminum alloys due to its smoother surface and better chemical resistance. Infinium Z has a brilliant light gold color.

For which applications is Infinium Z useful?

| Cutting Tools | Infinium Z should be used for machining applications where Infinium T has not performed well due to soft gummy materials sticking to the tool. |

| Forming Tools | Infinium Z should be used for forming and punching applications where Infinium T has not performed well due to soft gummy materials sticking to the tool. |

| Medical | Infinium Z can be used for surgical tools and will out perform Infinium T at times. Infinium Z has excellent biocompatibility for external and internal medical devices that come in contact with bone, skin, tissue or blood. |

| General | Infinium Z is a general purpose coating which can reduce abrasive and adhesive wear. It’s brilliant color also makes it a good candidate for decorative applications. |