DLC coatings

DLC coatings

Diamond Like Carbon

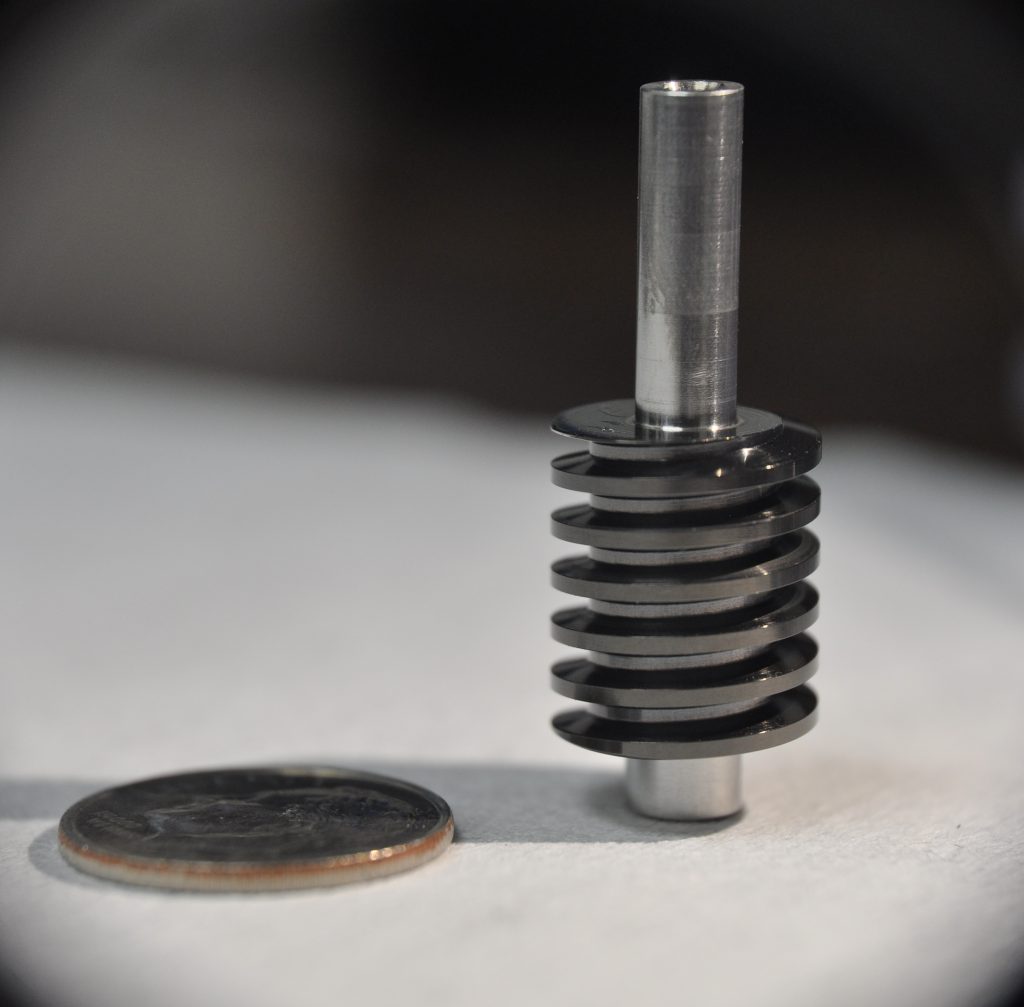

DLC is a very hard surface Superior to all other PVD coatings. The DLC coating is very adaptable and has excellent appearance that mirrors the material being coated. You can get a dull tactical finish on media blasted parts or a mirrored finished on polished parts. The DLC coating has excellent corrosion resistance and aids in ease of cleaning of of your finished product.

| Micro Hardness (HV) | 2000-3050 |

| Coefficeint of Friction | 0.1 – 0.05 |

| Thickness (um) | 1.5 – 3.0 |

| Color | Black-Gray *Varies with Substrate |

| Coating Temperature | 200° – 350°C |

Our DLC coating is tailored to have a combination of lubricity, abrasion, and corrosion resistance. Being a type of dry lubricant film, it performs well in bearing and gear applications where two mating surfaces have sliding contact. On cutting tools, DLC has worked very well with abrasive material such as wood and aluminum. Black in color and resistant to fingerprinting, this is also an ideal coating for cosmetic purposes.

In general, HCCs have a low coefficient of friction and good chemical resistance. The hardness of an HCC can be tailored to match a specific application.

Hardness Carbon Applications

Cutting Tools

- Reduces cutting forces and chip welding

- Increases wear resistance in abrasive materials

- Excellent for wood working

Forming Tools

- Forming dies and punches

- Reduces abrasive wear and friction

- Best in forming operations kept below 400°C

Automotive

- Improves component lifetime

- Reduces friction and lubrication needs

- Increases power and improves fuel efficiency

- Improves run-in times

- Reduces sliding friction

- Prevents seizure in dry conditions

Medical

- Maintains cell integrity with no inflammatory response

- Excellent bio-compatibility with prosthetics, catheters, and implants

- Increased lifetime of medical instruments

General

- Decorative applications

- Easy to clean